无锡锦业智能装备有限公司

手机:13706174296

13222839073

邮箱:sales@wx-jyjx.com

传真:0510-88159195

热线电话:0510-88158186

1. Technical parameters技术参数:

1.1 Steel Coils钢卷

Coil thickness: 1~6mm

Coil width: 100~650mm

Material of coils:Q195,Q235A, Q450

原料卷板厚:1~6mm;

原料卷板宽:100~650mm;

原料卷板材质:Q195,Q235A、Q450;

Coil ID:φ508mm

Coil OD: ≤φ1800mm

Coil weight: ≤12.5T

原料卷内径:φ508mm

原料卷外径:≤φ1800mm

原料卷重量:≤12.5T

1.2 Machine设备

Slitting precision: width tolerance ±0.1mm, Camber on strips:0.3mm/m better than GB709-88, GB704-88..

Five for 6mm, 15 for 3mm and 20 for 2mm.The finest finished strip 12.7mm, The widest101mm (custom knife)

Slitting shaft: φ205mm

Slitting knives: ID205×OD330mm

Material of slitting knives: 6CrW2Si, HRC55°-60°

纵剪精度:宽度允差:±0.1mm、侧弯允差:0.3mm/m,优于GB709~88的规定(扁钢GB704-88);

6mm分5条,3mm分15条,2mm分20条。成品条最窄12.7mm,最宽101mm(定制刀)

纵剪刀轴直径:φ205mm;

纵剪刀片规格:ID205×OD330mm

纵剪刀片材质:6CrW2Si, HRC55°-60°;

随机配22片 刀片供客户选择

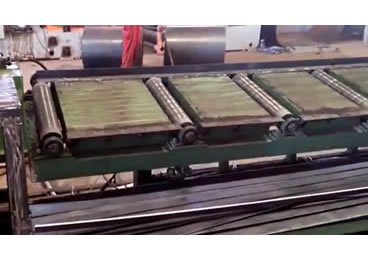

Leveler: 2+13 rollers.

Leveling roller: φ125mm

Material of leveling rollers: 40Cr, surface hardness: HRC52-55°

矫平机:2+13辊

矫平辊径:φ125mm;

矫平辊材质:40Cr,表面硬度HRC52-55°

Land occupation占地:about 25m x 6m

Total installation power总功率:210KW

2. Technical flow工艺流程:

Coil preparing saddle, Coil-loading car→12.5T single mandrel uncoiler→pinch feeder→side guide & press→ disc slitting → scrap reeler→transmission table→2+13 leveler→encoder→shear →overturn stacker. Include hydraulic system and electric system 备料台,上料小车→单臂开卷机→送料→导向、压料→纵剪(90KW DC)→收边丝(5.5KW,2台)→过桥→2+13矫平(75KW)→编码定尺→横切→垛料翻转台(6米),液压系统,电控系统(PLC)

3. Description of each equipment设备组成:

3.1.Coil Preparing saddle, Coil-loading Car备料台,上料小车

To put a coil on saddle, coil car come under the coil and lift the coil up.

Coil car Structure: Four wheels, car body made by welding

Driving motor: 1.5kw cycloid pin-wheel motor

Up-down movement driving: hydraulic cylinder Φ150×500mm

Up-down moving distance: 500mm

放一卷料在备料台上,小车开到卷料下面将钢卷顶起。

结构形式:四轮行走式,钢制焊接结构件。

传动动力:1.5kw针轮摆线电机。

升降动力:液压油缸Φ150×500mm。

升降行程:500mm。

3.2.Single Mandrel Decoiler单臂开卷放料机

Structure: cantilever hydraulic expansion by connecting-rod.

Uncoiling drum: Φ508×700mm, expansion range: Φ460~Φ520mm.

Hydraulic cylinder for expansion: Φ150×100mm

Hydraulic cylinder for uncoiling shaft support: Φ75×300mm

Brake style: pneumatic pressure-regulating brake

Overarm press roller: Φ200×200mm, driven by 2.2KW cycloid motor

Coil max width: 650mm

Coil max OD: 1800mm

Max coil weight:12.5T.

结构与形式:液压滑块内涨式。

放料卷筒规格:Φ508×700mm。涨缩范围:Φ460~Φ520mm。

涨缩油缸规格:Φ150×100mm。轴端液压支撑油缸:Φ75×300mm

制动方式:气动调压制动。

压料辊: Φ200×200mm,2.2KW摆线电机链轮链条驱动

适用卷带宽度:650mm。

适用卷带最大外径:1800mm。

适用卷带最大重量:12.5T

3.3 Hydraulic Pinch-feeder 液压送料机构

Composed of base, stand, roller seat, double pinch-feeding rollers, hydraulic lifting & pressing-down mechanism for up roller, motor & reducer and coupler

Hydraulic cylinder for up-down moving of upper roller: Φ63 x 100mm

Double rollers: Φ140 x 700mm, 40Cr

Motor & reducer: 4KW cycloid motor

由机座、机架、轴座、二根夹送辊、上夹棍液压提升压下机构、电机减速机和联轴器

上辊升降油缸:Φ63 x 100mm

双辊:Φ140 x 700mm, 40Cr

电机减速机:4KW摆线电机

3.4.Side guide & press roller导向压辊机构

Composed of guide roller base, sliding side panels, adjusting hand wheel, two pairs of vertical rollers,one pair of press rollers, manual up-roller adjusting mechanism, etc.

由导轨式机座、滑动侧板、调节手轮、两对立辊、一对压料辊、上轮调节机构等组成。

Side guide range纠偏范围: 100-650mm

Press roller压料辊: Φ100 x 700mm.

3.5.slitter纵剪机组:

Include two parts: drive part and machine part

Drive part is composed of base, 90KW DC motor, 650 speed reducer, double speed shift, distribution gearbox,clutch, universal joints, etc.

Machine part is composed of fixed stand, sliding stand, mechanism for sliding, double slitting shafts, the mechanism for up shaft lifting & pressing-down, etc.

Include 36 pcs knives, one group of spacers, one group of rubber rings, etc.

纵剪机组:由动力、主机两部份组成。

由动力座、90kw直流电机、650减速器、双档变速机构、对牙分配箱、离合器、万向节、等组成。

主机部分:由固定式机架、移动机架、移动调节机构、二根纵剪刀轴、刀轴提升压下机构组成。

配套刀片22片、刀垫一组、橡胶圈一组等组成。

3.6.Scrap reeler边丝机, 2sets两套

由边丝轴、边丝盘、减速器、5.5kw电机组成。

Composed of reeling shaft, reeling wheel, , speed reducer, 5.5KW motor, etc.

3.7.Transmission table过渡台(客户自备Customer prepare by self)

Composed of table rack and plates on the rack由机架、托板等组成

Composed of lever, lever's drive, and encoder to fix length.

Drive is composed of base, 75KW AC motor, ZQ650 speed reducer, dual speed shift, distribution gearbox , brake, and 13pcs universal joints

Leveler is composed of base, frame, bearing seats of up rollers and down rollers, 2+13 rollers, press-down device( one side, 2.2KW x 2 cycloid speed reducers and worm screw rod, connecting to manual hand wheel screw rod by synchro sticks) hydraulic up-down moving of upper pinch roller.

由动力部分、主机部分、编码定尺部分组成:

动力部分由动力座、75KW直流电机、ZQ650减速器、双速变档、联轴器、制动器、动力分配箱和万向联轴器等。

主机部分由机座、机架、上下辊轴承座、2+13根辊、电动提升压下机构(一侧为2.2kwx2摆线针轮减速器和蜗轮蜗杆,同步杆连接另一侧手轮调节蜗轮蜗杆)、上夹辊提升机构等组成。

3.9.液压切断机 Hydraulic shearing machine

由机架、导轨、滑动刀架、液压切断机构。

Composed of frame, guide rail, sliding knife holder, hydraulic cut-off mechanism.

3.10.Overturn Stacker翻料台

Composed of frame, roller table, 2.2KW drive motor and reducer, hydraulic overturn mechanism, etc.

Length of finished flat bars: 6m

由机架、辊道、2.2KW输送电机减速器、液压翻转机构等构成。

成品扁钢长度:6米

3.11.Hydraulic system液压系统

Composed of hydraulic station, valve plate, valves, high-pressure hoses, seamless tubes, joints, etc.

由液压站、阀板、各种阀、高压软管、硬管、接头等组成。

Pump motor油泵电机: 7.5KW

Hydraulic pressure压力: 12Mpa

Volume of oil tank油箱容积: 450L

Japan Yuken oil pump日本油研油泵。

3.12 Electric control system电控系统

A whole set of electric control system

includes one control cabinet and two operator panels.

Siemens AC drivers, Siemens PLC and touch screen, Yoko encoder

Schneider electric parts

Total Installation power: about 210KW.

全套电气系统:包括一台控制柜、2台操作柜

装机功率:约210KW

3.13 Configuration配置

| Sr. | Components | Brands |

| 1 | S7-1500 PLC, HMIPLC 和触摸屏 | Siemens 西门子 |

| 2 | AC motors交流电机 | Beide贝得 |

| 3 | AC converters交流变频器 | 正旋 |

| 4 | Hydraulic valves and pump,油泵 | Yuken, Japan日本油研 |

| 5 | Pneumatic valves and cylinders气动阀,气缸 | 亚德客 |

| 6 | DC motor and controller电机控制器 | 590 |

| 7 | Bearings 轴承 | 哈尔滨 |

| 8 | Electric parts电气元件 | Schneider施耐德 |

3.14 Buyer to prepare需方自备:

Power source switch电源总开关

Cables and wires现场电线电缆

Electric conduits串线配管

Air compressor (pressure 1.2Mpa, flow: 0.9m³/min)

空气压缩机:压力为1.2Mpa,流量为0.9m³/min。

Oil in gearbox( 50# mechanical oil), hydraulic oil(N46).

齿轮箱油(50#机械油),液压箱油(N46液压油)

Protection fences护栏